Laser processing heads

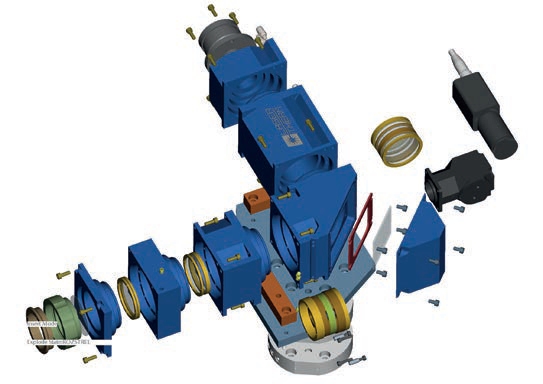

Design and development of processing heads for laser welding, hardening and cladding technologies according to customer requirements.

The development is focused on the stability, robustness, cooling, modularity minimal installation dimensions and weight of laser processing heads for high power industrial applications.

The results of the development are then tested by real load of the LaserTherm custom production. Feedback of process ensures a high-quality and practical product ready for heavy industrial operation.

We can achieve all this thanks to our own real experiences from everyday practice.

TOP 5

- Robust construction with sophisticated cooling system

- Quick exchange of optical components

- Long-term stability in heavy industry

- Good performance cost/ration

- Technical and service support directly from the manufacturer

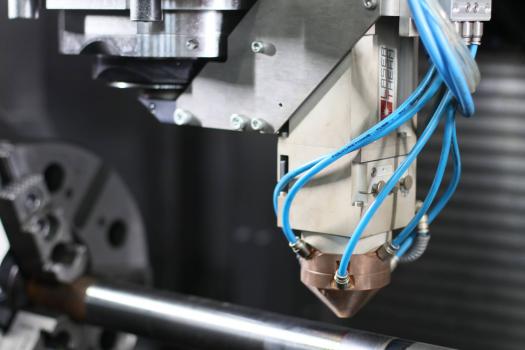

Welding heads

Usual spot size: | 0,2–3 mm |

Welding speed: | 10–10 000 cm/min |

Laser power: | 200–10 000 W |

Accessories: | airknife, on-line welding diagnostics, seam tracking system, wire feeding, camera |

Weight: | 4–10 kg (according to accessories) |

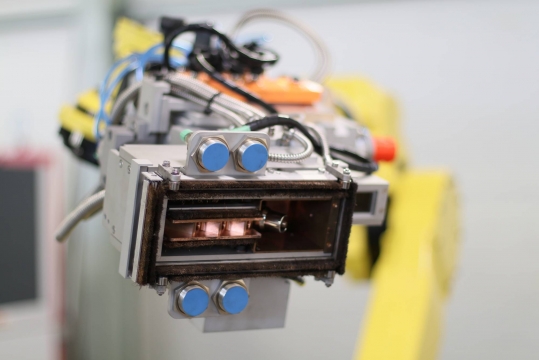

Hardening heads

Usual spot size: | According to customer requiremens, often: from 10 × 10 mm2 to 100 × 10 mm2 |

Hardening speed: | 10–100 cm/min |

Laser power: | 1000–14 000 W |

Accessories: | pyrometer, airknife, thermovision |

Weight: | 4–10 kg (according to accessories) |

Cladding head with circular spot

Spot size: | 1–8 mm |

Power: | 1 000 – 6 000 W |

Use: | For hard to reach surfaces |

Head position: | Cladding in various head positions |

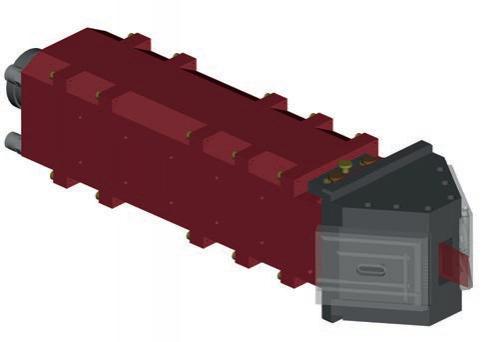

Cladding head with rectangular spot

Usual spot size: | 10–30 × 2–3 mm² |

Laser power: | 2 500 – 14 000 W |

Use: | For large-area cotings |

Head position: | Cladding in vertical position |

Materials suitable for laser cladding: Co base alloys (Stellite), Ni base alloys (Inconel), Fe base alloys (comon, stainless or tool steels), bronze alloys, cermets and others