Energy industry

The connection between the energy industry and Lasertherm company is in several areas. One of them is the surface treatment (hardening, cladding, precipitation hardening and welding) of key components of transmission systems. The service life of heavily loaded blades, bearings or several-ton spindles is prolonged thanks to this treatment. Another connection is, for example, in the boiling of bearing shells. Thanks to laser technology it is possible to realize previously unimaginable requirements.

Steam turbines

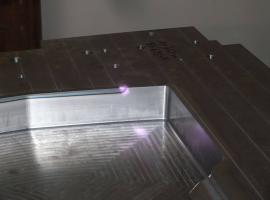

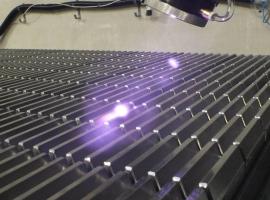

The gradual increase of steam parameters in steam turbines imposes high demands on used materials and methods of their processing. Laser technology offers a wide range of options for increasing the efficiency and durability of turbine systems and their parts. Major applications of laser technology for power engineering include erosion protection of the leading edges of turbine blades, either by laser hardening (in case of hardenable steels), by laser precipitation hardening (in case of precipitation hardening steels) or by laser cladding (in case of non-hardening steels).

Application examples:

Nuclear energy

The use of nuclear energy is currently one of the most promising ways to obtain energy.

The demands of nuclear power engineering on corrosion, temperature and radiation resistance of materials create a space for utilization of modern methods of processing components for nuclear industry. The preparation of nickel protective cladding with high corrosion and radiation resistance and welding of special austenitic steels with a high boron content belongs to the interesting applications of laser technologies for the nuclear industry.

Application examples:

Reference projects

Do you have questions or want to send an inquiry?