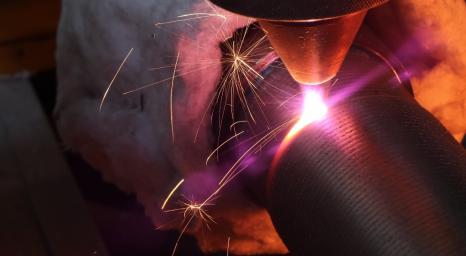

Laser cladding

Precise method producing functional coatings for lifetime and functionality enhancement of mechanical parts. According to requirements is possible to produce coatings with the metalurgical bonding to the base material with resistance against wear, oxidation, corrosion and for applications at elevated temperatures (up to 1000 °C). Method is suitable for manufacture, renewal and repairing of shafts, flanges, pivots, broaching tools, turbine blades and functional surfaces of moulds and tools.

Principle

The metal powder or wire is fed to a laser beam, where this material is melted together with the base material of the part and a deposition layer is formed on the surface of the part. A metallurgical bond is formed between the deposition layer and the base material, guaranteeing excellent adhesion between the cladding layer and the part.

TOP 5

- High surface layer hardness and abrasion resistance, high temperature stability and corrosion resistance

- Excellent adhesion and cohesion of the coating without porosity

- Low thermal influence of the base material

- High efficiency and reproducibility

- Possibility of cladding in any thickness and 3D shapes, large selection of additional materials

Additional materials

- Stainless steels (AISI 3xx and 4xx)

- Structural steels (42CrMo4)

- Tool steels (M2, M35, H13, H100)

- Cobalt alloys (Stellit, CoNiCrAl, Tribaloy)

- Nickel alloys (NiCrSiB, Nimonic, Inconel, Hastelloy)

- Bronze alloys

- Cermets (WC-Co, WC-Co-Cr, CrC-NiCr)

Applications

Laser cladding applications are used to tool cutting edges, steam and gas turbine components, pulleys, ropes, rollers, drive wheels, shafts, winding drums and other moving parts, tool parts and pins.