Laser welding

Laser welding is used primarily for parts where the emphasis is placed on high welding speeds, precise, high quality weld joint without contamination, porosity and with low thermal deformation of the surrounding material. High process speed, stability and easy implementation of automatic welding process and possibility of on-line diagnostics of the weld make from the laser welding favorite method for industrial applications focus on effectivity and volume. Laser welding is contactless and without electrodes. Laser technology has a constant output during welding. With stable adherence to other inputs such as material and fitting, a quality output of the laser welding system can be guaranteed. We can supply laser welding technology as a complex or in the form of a servis we provide.

TOP 5

- Optimal technology for automation

- High speeds of welding, precise and high-quality weld without cracks, dirt, and pores

- Minimal deformation and heat affected zone

- Welding of conventionally non-weldable materials

- Welding with and without additional material

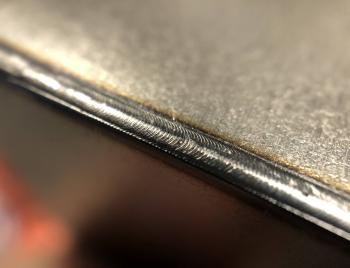

Laser weld purity

The effectiveness of laser welding is not only in the speed of weld formation. It also has many other benefits. An indisputable advantage is, for example, the purity and shape of the weld. While with other methods the welds have to be subsequently cleaned and ground, with laser technology it is possible to achieve clean weld with a shiny metallic colour. Logically, this result in time savings not only in multiple welding speed, but also in time for subsequent grinding and cleaning. The final appearance of the weld is influenced by a combination of laser optics, power, welding speed and the method of weld protection.

Safety is very important point in the laser world. Laser safety is solved at the design of laser workplace, at the installation and then during the process too. The protection of the laser welding process is subject to the safety standard ČSN 60825.

The second important point is the preparation of parts before the process itself. Laser technology is very accurate, so it requires stable preparation before welding.

Laser welding speed

A key parameter in laser welding is speed. Compared to other welding technologies, this parameter is the most significant. Welding speeds with laser welding range from meters to tens of meters per minute. These parameters ban be used for basic orientation.

2 kW - 2 mm penetration depth - 2 m/min

With increasing power, the laser welding speed or the penetration depth can be increased proportionaly. At thinner materials, the required laser power can be reduced, or the processing speed can be increased.

Fundamentals in the field of laser welding

Laser welding is one of the modern methods of joining various metallic and non-metallic materials. It belongs to the group of fusion welding. It is a non-contact method where a laser is used to melt the material. This method provides a non-detachable joining of components. Laser welding is a welding method where no additional material is needed. Laser welding can take place in atmospheric conditions as well as in a protective atmosphere.

Principle of laser welding

During laser welding, the laser beam is focused on the surface of the part. The materials are melted and mixed along the joint and subsequently cooled to form a weld.

Deep penetration welding

Deep penetration welding is also referred to as keyhole welding. This welding method requires a high-power laser with a density of about 1 MW/cm2. The laser beam is focused on the surface of the welded material and melts and evaporates the metal at the point of impact. The molten material is forced out by steam and a narrow and deep hole is created - a keyhole. The molten metal flows around the keyhole and solidifies at the sides, creating a deep, narrow weld. The steam generated during this process is ionized and is called plasma. The resulting plasma is able to absorb the energy of the laser and thus increase the efficiency of material processing. The weld depth can be up to ten times greater than the weld width.

Heat conduction welding

Heat conduction welding works on the principle of melting the material at the joint followed by cooling to create a weld that does not need to be further modified. Heat dissipates based on the thermal conductivity of the material. The depth of the weld ranges from tenths of a millimetre to 1 millimetre. The weld width is always greater than the weld depth.

Applications of laser welding

Different types of materials can be welded using a laser. Good weldable materials include materials with a carbon content of up to 0.22%. Low alloy and austenitic stainless steels, aluminium alloys, magnesium alloys, titanium alloys, copper alloys and nickel alloys can be commonly welded. Lasers are also used in welding plastics and composites.

A great benefit of laser welding are high process speeds, which can be used mainly in mass production. Laser welding is also used in piece production. In both cases, a precise and high-quality weld is created without cracks, dirt, and pores. Robotic welding is widely used today. High accuracy and repeatability are guaranteed by robotization. Conventional welding methods are often replaced by laser welding.